HomeProduction SystemPOP/MES System

POP/MES System

We apply our state-of-the-art technology to the whole system,

which is thoroughly managed by putting in professional SI personnel.

We have established the systems like the point of production[POP] system and manufacturing execution system[MES] that enable us to collect,

analyse and monitor various kinds of information about production performance, workers’ activities, machine operation, product quality, etc and to control the production process, which leads to the production system suitable for high quality and profitability.

POP

– Point of Production –

Automatization of the machines and the plant system that can ensure more effective quality control by checking any unusual reactions during the operation of machines.

This enables us to collectively manage all necessary information about the monitoring and control of processes and machines, the tracking and control of quality information, the statistics of performance, warehousing, stock, the application of materials, personnel, production machines, etc by collecting the situation of production activities of the existing 4Ms(men, methods, materials and machines) in real time by means of the information system.

Smart Factory Monitoring of Woosung Ind. Co., Ltd.

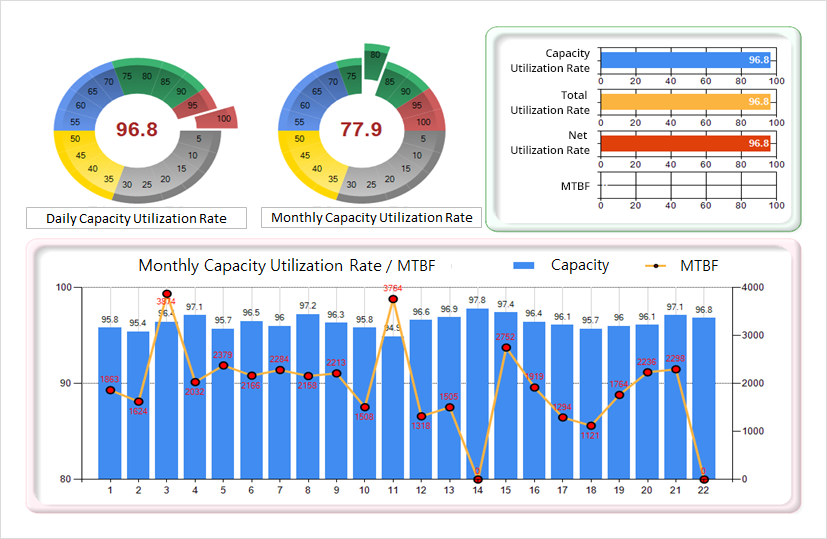

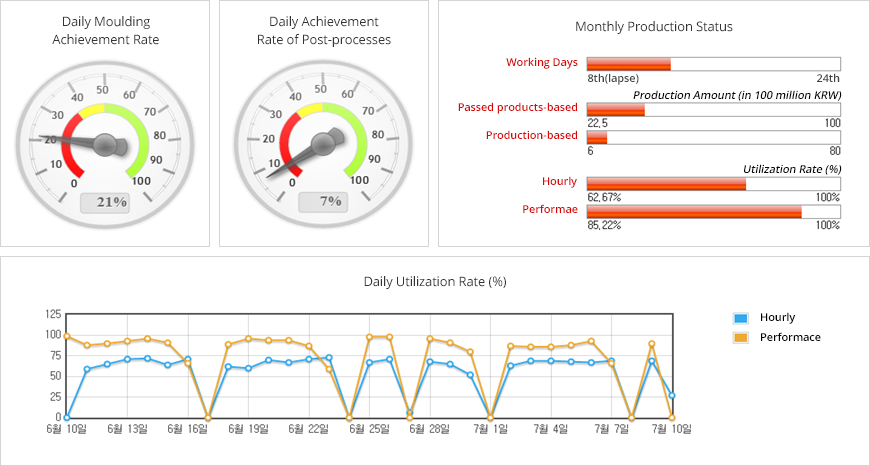

Production index System

- As an activity reducing any non-value added activities, it increases the efficiency of processes during the factory management by enabling us to responding to ususual field situations like unplanned downtime, defects or bottlenecks.

MES

– Manufacturing Execution System –

Smart Factory Monitoring of Woosung Ind. Co., Ltd.

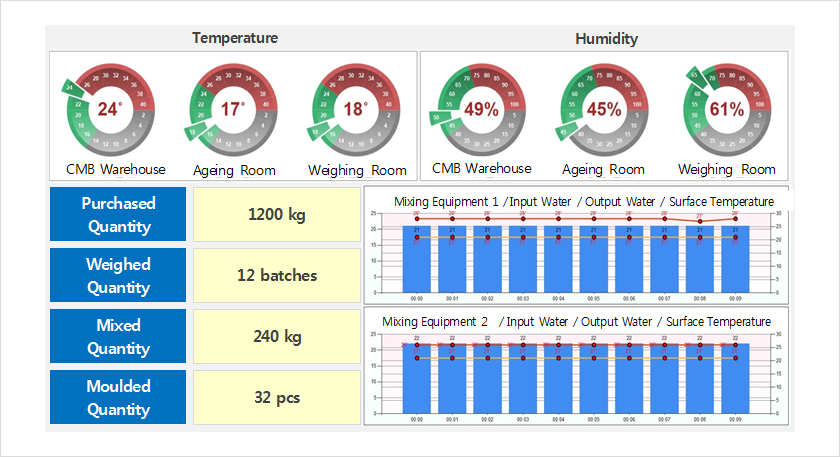

CMB Control System

- Any possible cause of defects can be removed by monitoring the logistic information and environmental factors in real time from the warehousing of materials, weighing and mixing to moulding.

- Its accurate real-time data enables us to properly instruct the plant activities, respond to any unusual situations and report them.

Smart Factory Monitoring of Woosung Ind. Co., Ltd.

Production Capacity System